Refurbishment

Upgradation /Refurbishment of Tower crane, Passenger hoist & Mobile tower crane reliable & economically

Cangraft Equipment Pvt Ltd Offers Refurbishment and upgradation solutions for all makes of tower cranes, mobile tower crane & Passenger Hoist. The core concept is to extend the life span. As machine age and the components reach the end of their Safe Working Period, they become unreliable. This results in escalated operating costs of the without any long-term value. Planned Refurbishment can make the machine more Safe, Reliable and capable for current Performance expectations. The Life Extension Program from Cangraft provides value compared to investment of a new Machine

Depending on the nature of industry and usage, the wear and tear is likely to differ. A critical review of the equipment any time after 5 years to evaluate its technical performance and economic operation is recommended. Refurbishment solutions could be a simple addition of a safety device on the crane and could extend to increase in span or

modification to Safe Working Load (SWL) of the machine.

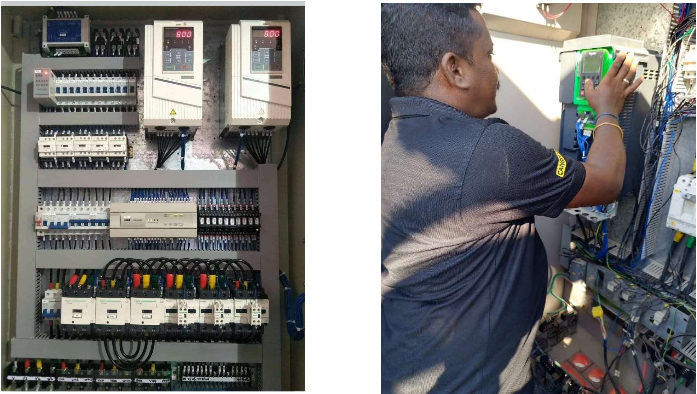

All type Control Panel, VFD, PLC Service & Installation.

Cangraft Equipment Pvt Ltd have been engaged in manufacturing, trading and importing a wide range of Tower crane, Mobile tower crane, Passenger hoist Control Panel.

We have a team of highly qualified professionals who are skilled in their respective domains. A variable-frequency drive is a type of adjustable-speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage. The integration of a human machine interface and programmable logic controller (PLC) provides a lean automation solution.

Lean manufacturing is a proven, powerful method to boost efficiencies in production processes. Similar concepts and practices that eliminate “waste”-unnecessary equipment and process steps-can be applied to the design, construction, and support of automation systems to enable increased productivity and reliability, yielding increased efficiency.

Faster machine design by providing an integrated development environment. Reduced machine construction costs by eliminating components and wiring. Reduced machine support cost and improved operation by centralizing remote access and administration

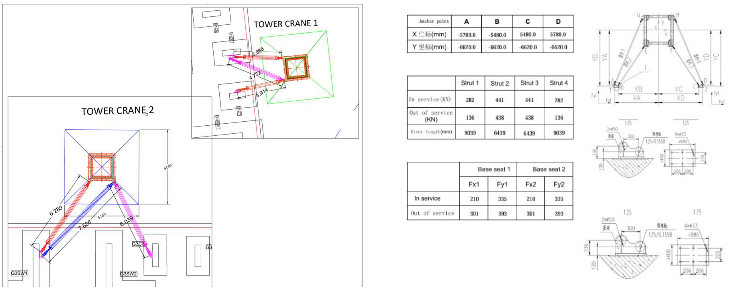

Tower crane anchorage/ I Beam support design, Load Reactions, Detail drawings Fabrication & In site Installation.

We are specialised in Design, Fabrication & Installation of anchorage for external tower crane, I beam for Internal tower crane. We have inhouse production unit which can fabricate & test material.

Annual maintenance check-up, Safety Health checks up with detailed check list for tower crane to reduce brake down.

Annual Maintenance is scheduled services for machine to essential to ensure the safety, reliability, and optimal performance. Regular maintenance helps prevent unexpected breakdowns, extends the lifespan of the cranes, and maintains compliance with safety regulations. Our comprehensive maintenance programs with detailed check list providing tailored solutions to meet the unique needs of different industries.

Safety Health check-up covers complete detailed Inspection of machine with check list including Structural components, wire ropes, Mechanisms, Electrical components, Hydraulics, Safety limit to avoid any potential hazards. Detailed training to Operator, Signal man & teams regarding safe operation of machine & personal safety. Wear & tear items , Fast moving spares recommendation for eliminate delay in operation & brake down

Any breakdown issue we can be attend in PAN India within 24 hrs

Our Service team are expertise in all type of tower crane, Passenger Hoist & Mobile tower crane troubleshooting, we are committed to provide throughout after service support for customer end to end solution.

All type of Manual erection, dismantling with Derrick crane & jacking up operation

Our service team is competent for Manual erection, dismantling with derrick crane in PAN

India.

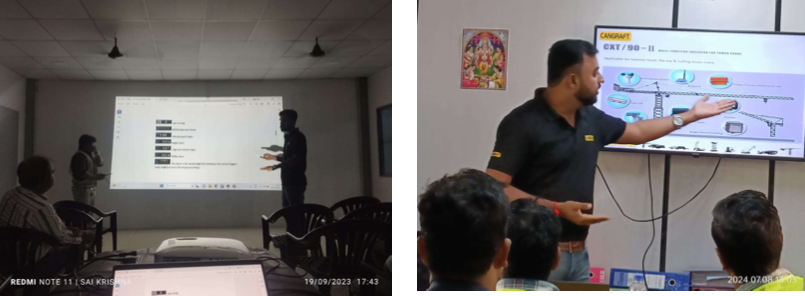

Anti-Collision Safe load Indicator Device Installation, Service & commissioning.

Anti-collision device is used to prevent risk of collision b/w tower crane moving parts & avoid damaged , injury. We provide service for all make Anti Collison Device , Safe load Indicator. Our team is specialised in the service of the same

Tower crane, Passenger hoist Bio metric device Installation & commissioning.

To prevent un authorised operation of machine we provide biometric device, which can be operated by touch key pad & numeric lock system. We provide customised device as per customer requirements

Operator, Customer Training-Technical consultation.

We provide technical training in all aspects of machine to customer

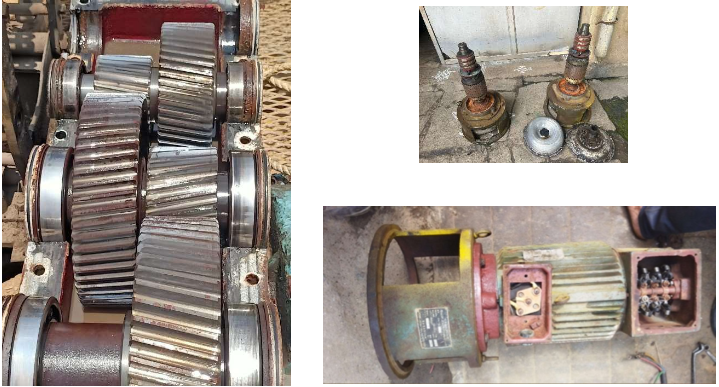

Repair of all Gear box, Rewinding of all motors.

We undertake overhauling & repairing of all type gear box & Maintenance repair of electric motors

Hydraulic pump station & Cylinder Repairing & Service

We provide service for tower crane Hydraulic system, Pressure value check & seal kit replacement